Reagents

Surface contamination: Chemical cleaning

The surface corrosion is the damage of the stainless steel passive layer, losing stability and therefore the capacity to resist the corrosion, is due to the characteristics of the application (composition, structure, mode), as well as the aggressive environment to which the stainless steel is subjected.

For a good perform of the stainless steel all this corrosion must be removed. Depending on the level of corrosion, we may apply the following products:

Pickling

This product is especially indicated for cleaning welds and removes stains of oxides.

CONTENT: It has a 10% nitric acid solution with 2% hydrofluoric acid.

Cleaner

Surface rusted areas are symptoms of contamination.

This product is especially indicated for cleaning and restoring surfaces, whatever its type of finish, without damaging or altering it (2B / 2R / Satin / Grinded).

Passivating

It is excellent for decontaminating slightly oxidized surfaces and for stabilizing the passive layer after a pickling process.

The Passivant guarantees the passive layer recovery process in about 3 hours.

Passivation is a natural process for stainless steel in which its "passive layer" (chromium oxide) is renewed. This process can take between 2 to 15 days during which the stainless steel is unprotected.

CONTENT: Nitric acid with a concentration of around 20%.

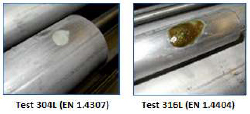

Molybdenum Reagent

The molybdenum Reagent is used in materials of stainless steel series 300 to test the presence of molybdenum and to differentiate grade 304 (without molybdenum) from 316 (with molybdenum).

With this simple chemical test we will be able to verify if the piece / material of stock or scrap of stainless steel contains molybdenum and demonstrate the quality in a few minutes.